Fiber lasers deliver exceptional beam quality for ultra-precise cutting.

Cut thin materials up to 3x faster than CO2 lasers with superior edge quality.

Up to 50% lower power consumption compared to traditional laser systems.

Solid-state design with no moving parts in beam path ensures reliability.

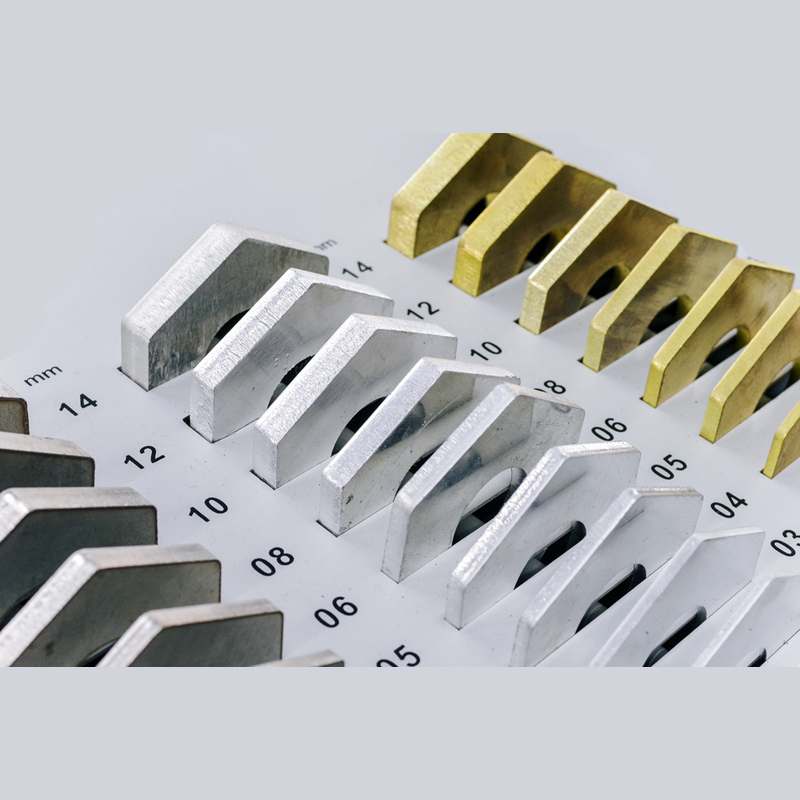

High-speed cutting for HVAC, automotive, and general fabrication

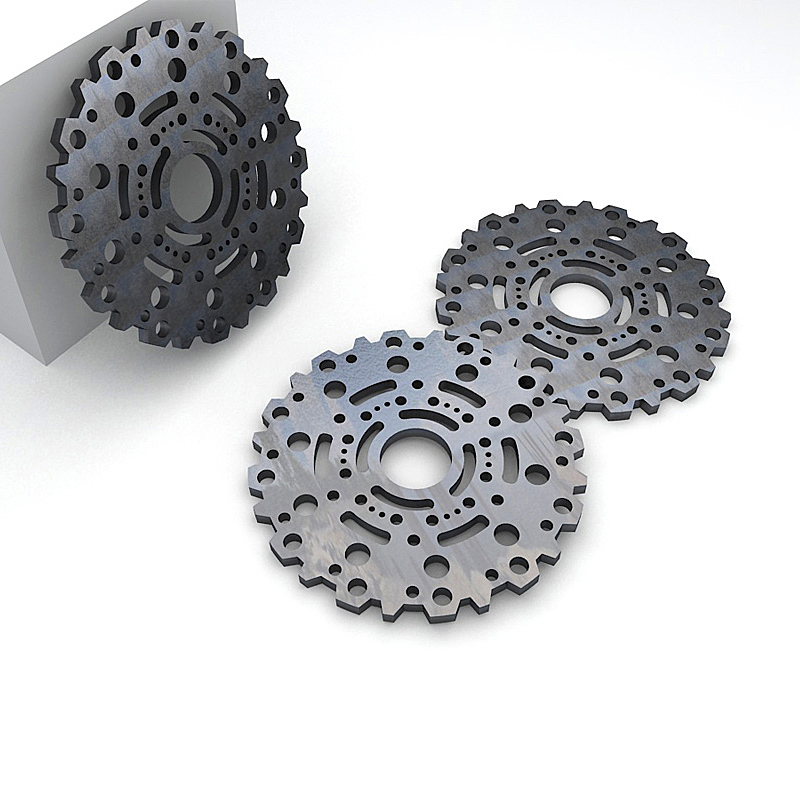

Medical devices, electronics, and aerospace components

Decorative panels, signage, and structural components

Versatile cutting for diverse customer requirements