CNC Routers

MR Series

The MR Series Entry-Level CNC Router delivers professional CNC capabilities in an accessible, user-friendly package.

POWER SUPPLY

220V Single Phase

220V Single Phase

CONTROL SYSTEM

XDW

XDW

MOTOR TYPE

Servo Motor

Servo Motor

COOLING SYSTEM

Water Cooling

Water Cooling

SPINDLE POWER

4000 Watt

4000 Watt

SPINDLE RPM

30000 RPM

30000 RPM

Model: MR48 From $31000.00

In stock

In stock

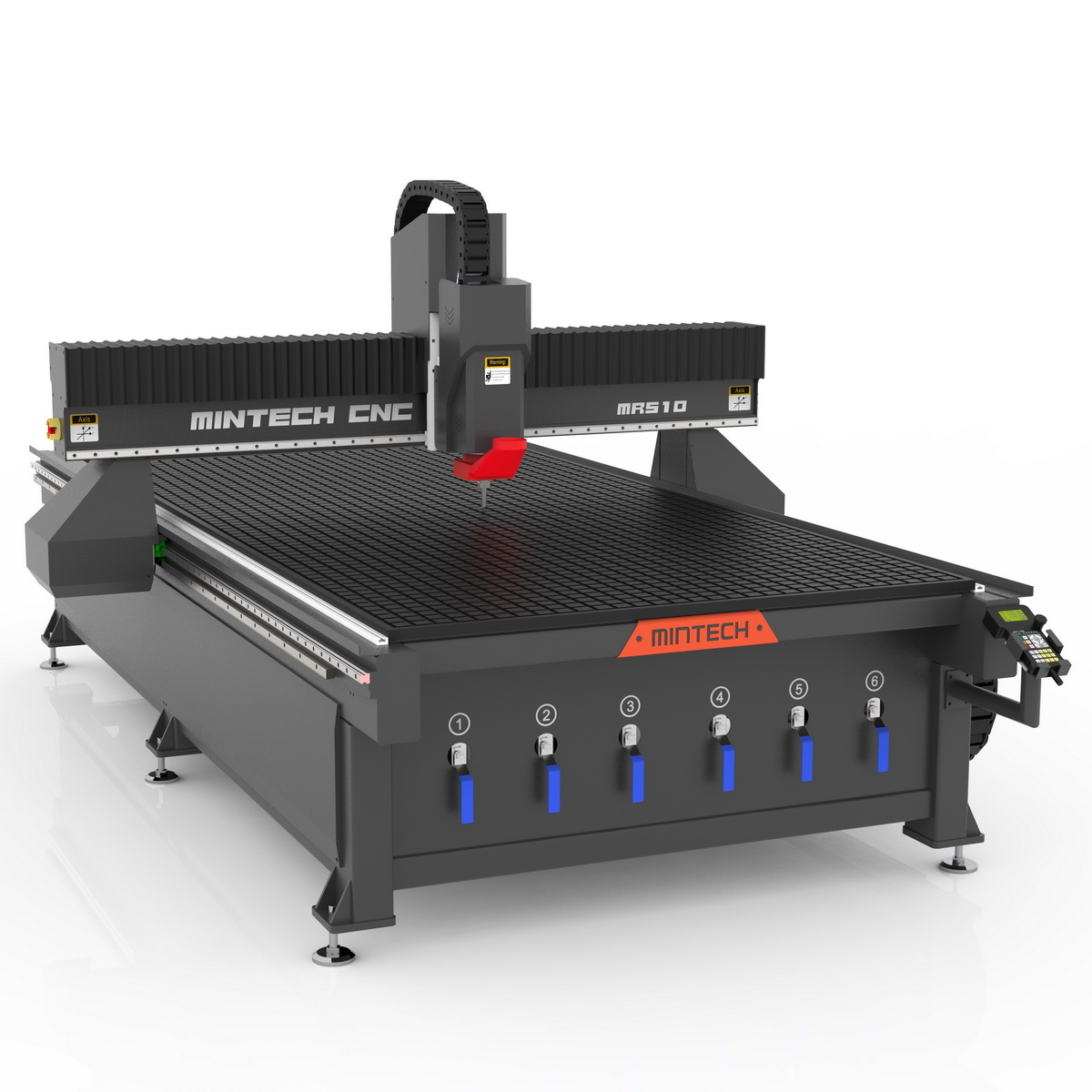

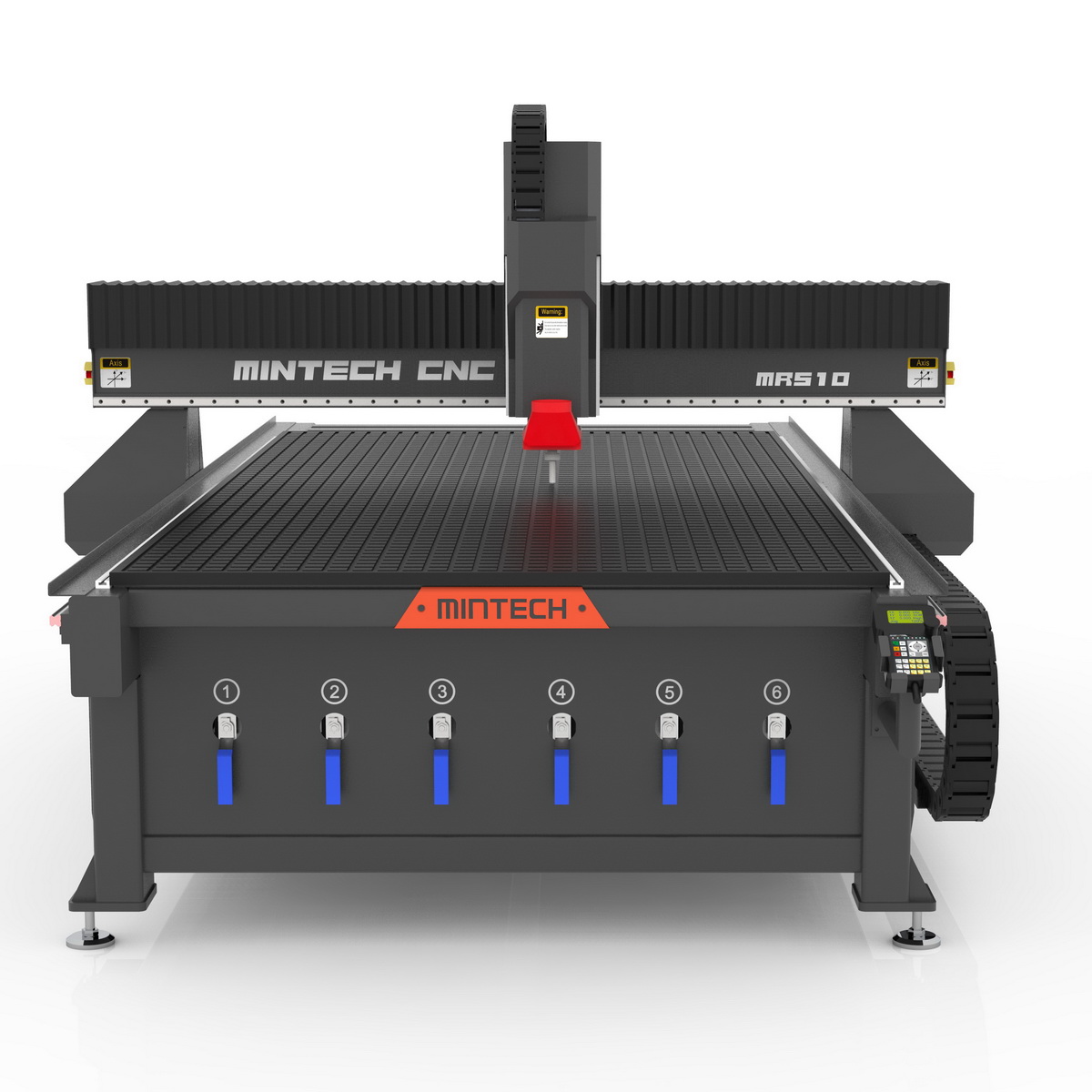

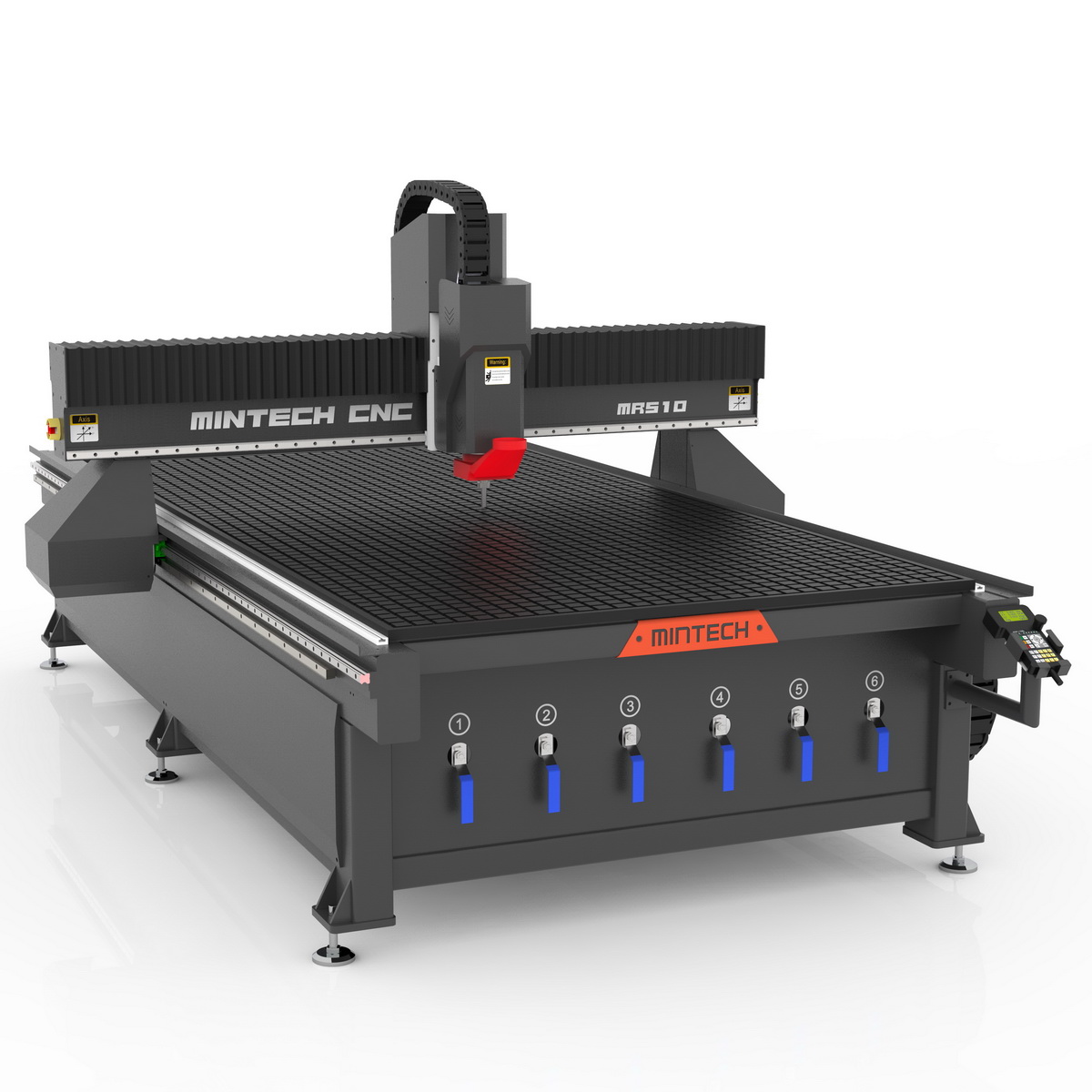

Model: MR510 From $34000.00

In stock

In stock

* Free shipping within the continental U.S. on all online orders

Technical Specifications

| Model | MR48 | MR510 | |

|---|---|---|---|

| Working area | 4'× 8' ( 1250 × 2500 mm ) | 5' × 10' ( 1530 × 3060 mm ) | |

| Dimensions | 122" × 87" × 69" ( 3100 × 2200 × 1750 mm ) View image | 150" × 97" × 69" ( 3800 × 2450 × 1750 mm ) View image | |

| Weight | 3400 lbs | 3900 lbs | |

| Work Area and Capacity |

|

||

| Control System |

|

||

| Motion and Drive |

|

||

| Spindle |

|

||

| Cooling method | Water Cooling | ||

| Power and Utility Requirements |

|

||

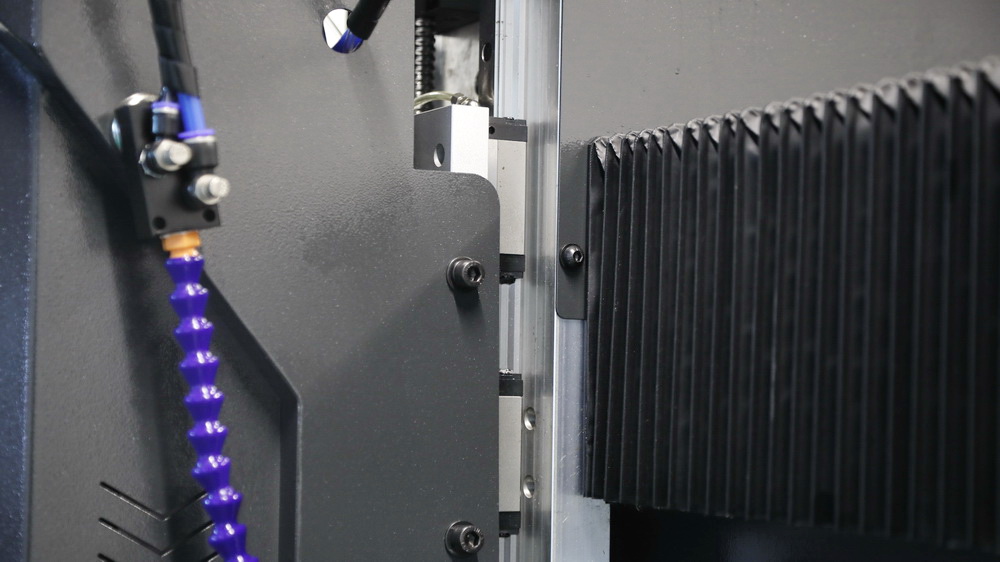

| Misting / Lubricating System | Includes flexible loc-line nozzles for adjustable coolant or mist delivery to the cutting area, ensuring efficient lubrication and extended tool life. | ||

| Environmental Requirements |

|

||

| Available Configurations | Optional high-resolution CCD camera for precise positioning and material alignment. | ||

| Advantages |

|

||

MR48 - CNC router for woodworking

MR510 - CNC router for sign making

Need Technical Support?

Our engineering team can help with product selection and configuration.

+1 (909) 755-1011

admin@mintechusa.com

Contact Engineering