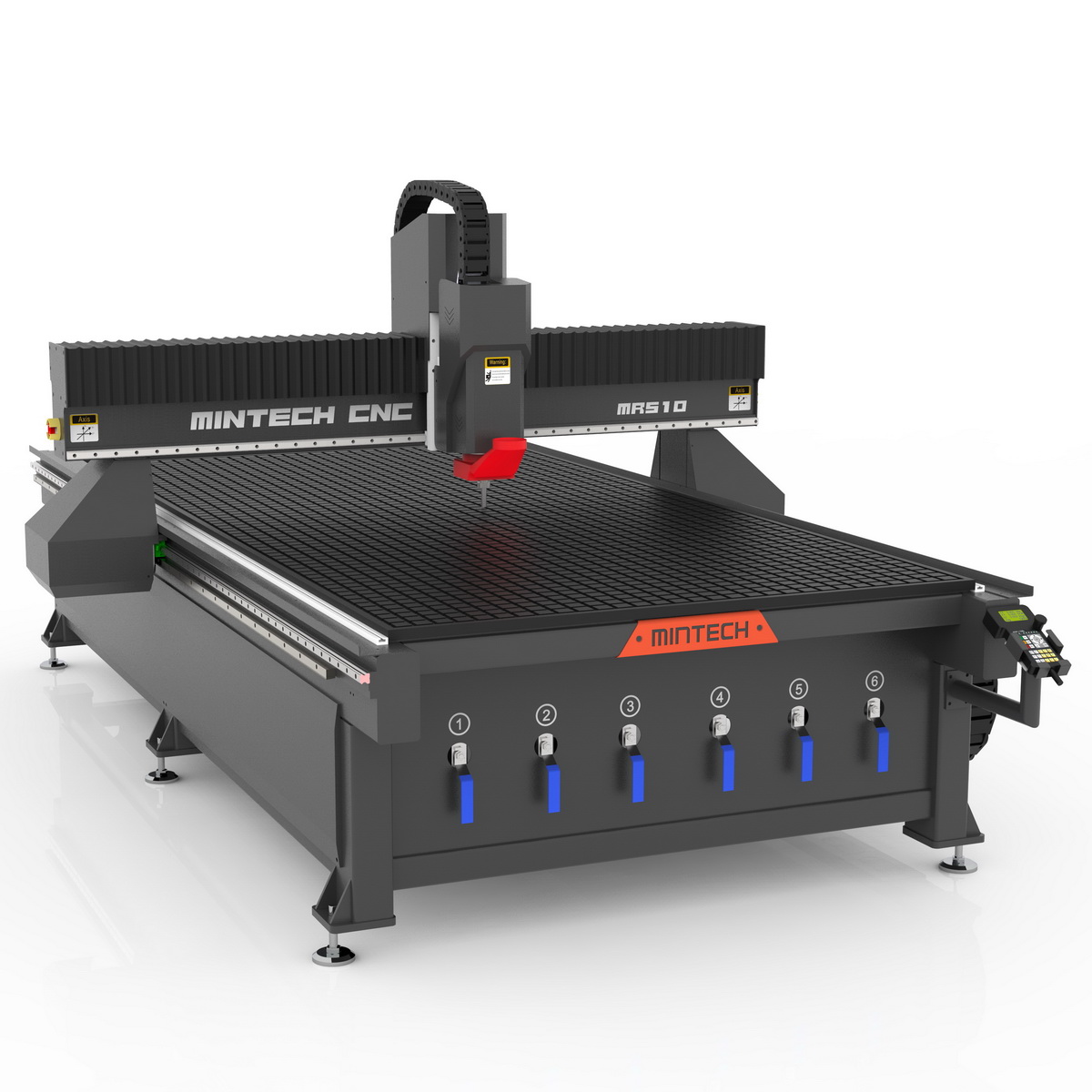

CNC Routers

* Free shipping within the continental U.S. on all online orders

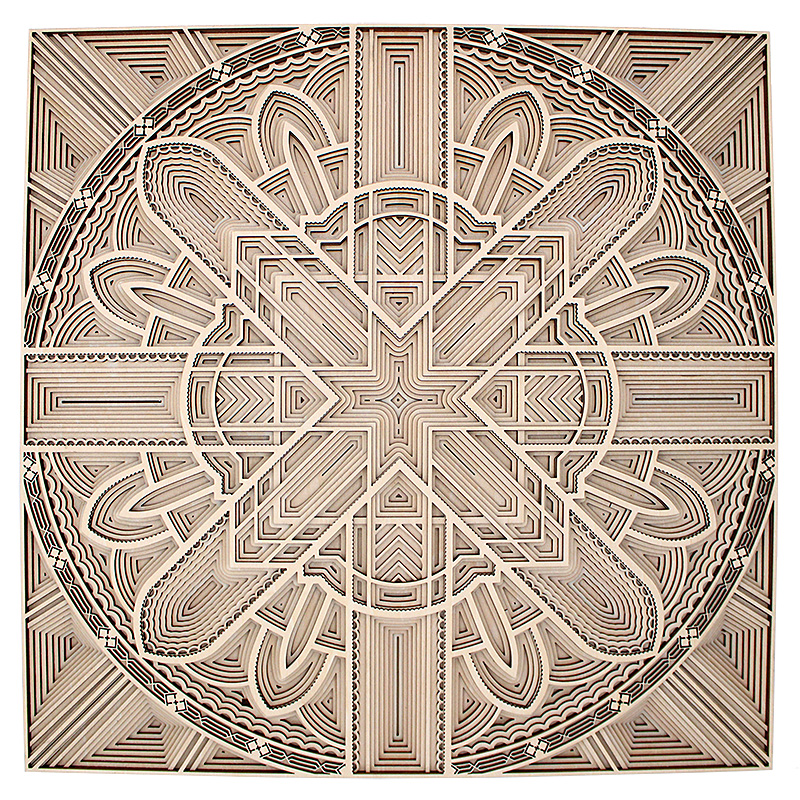

TR Series

Cost-effective CNC router with powerful spindle and automatic tool-changing system, Offering exceptional performance and value for small and medium-sized enterprises.

POWER SUPPLY

220V Three Phase

220V Three Phase

CONTROL SYSTEM

XDW

XDW

MOTOR TYPE

Servo Motor

Servo Motor

COOLING SYSTEM

Air Cooling

Air Cooling

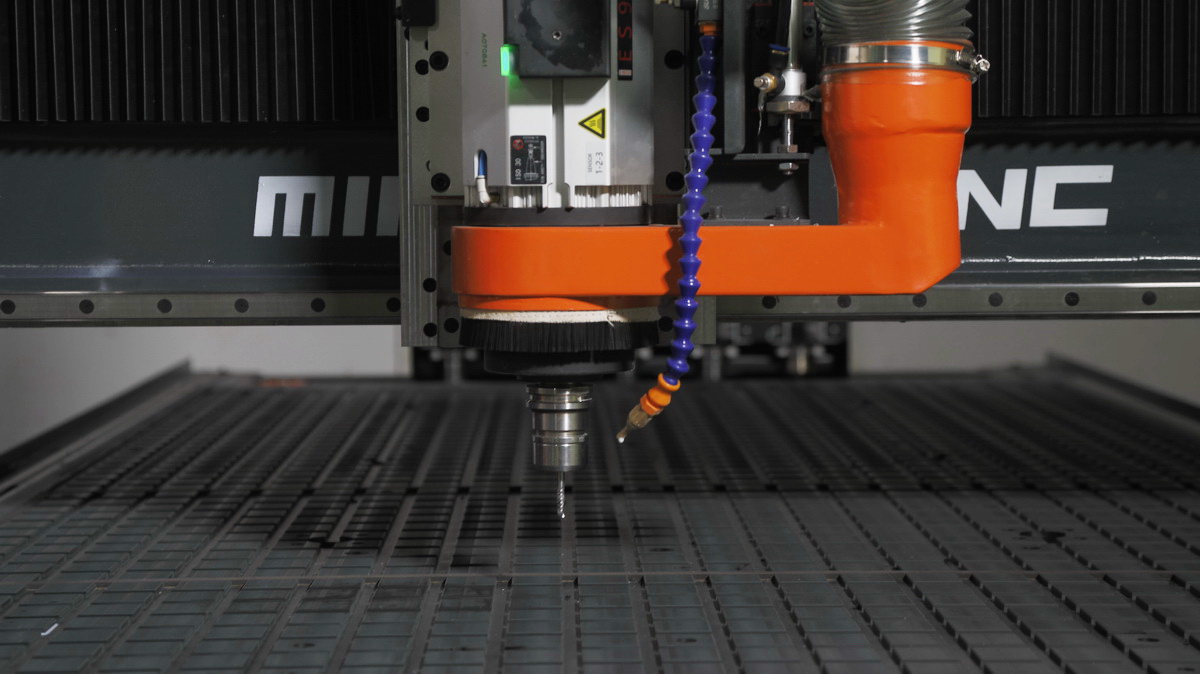

SPINDLE POWER

9000 Watt

9000 Watt

SPINDLE RPM

24000 RPM

24000 RPM

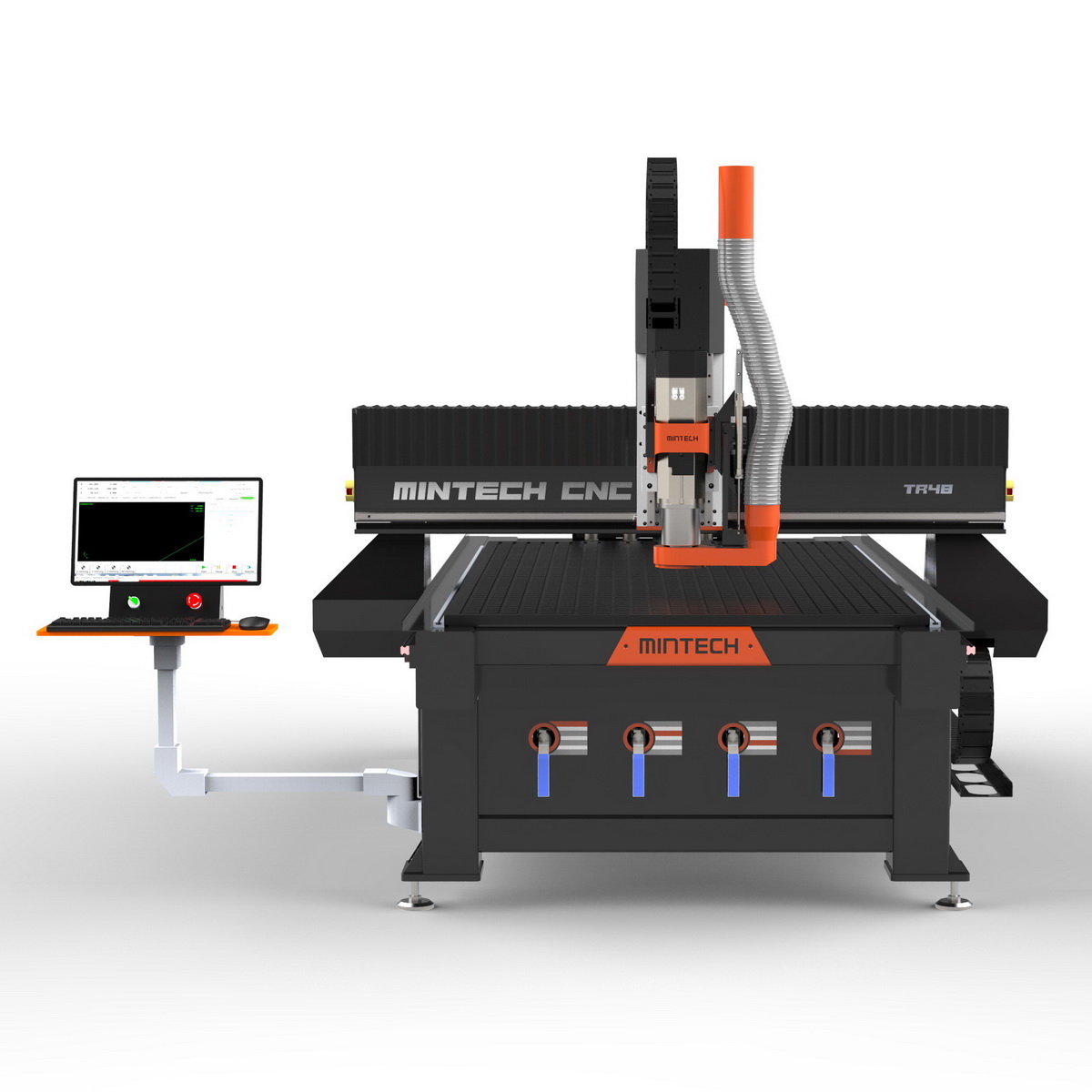

Model: TR48 Starting at $46000.00

In stock

In stock

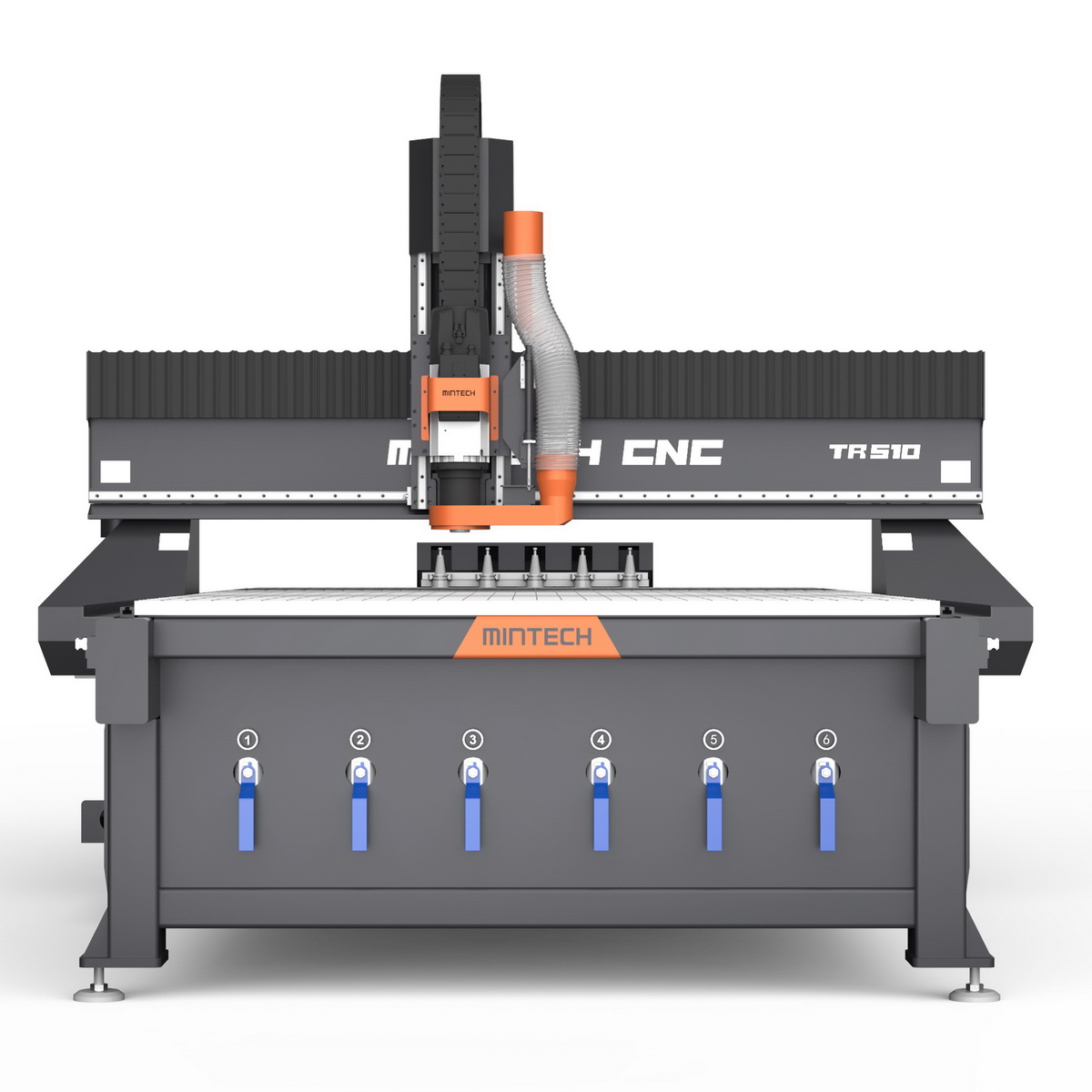

Model: TR510 Starting at $51000.00

In stock

In stock

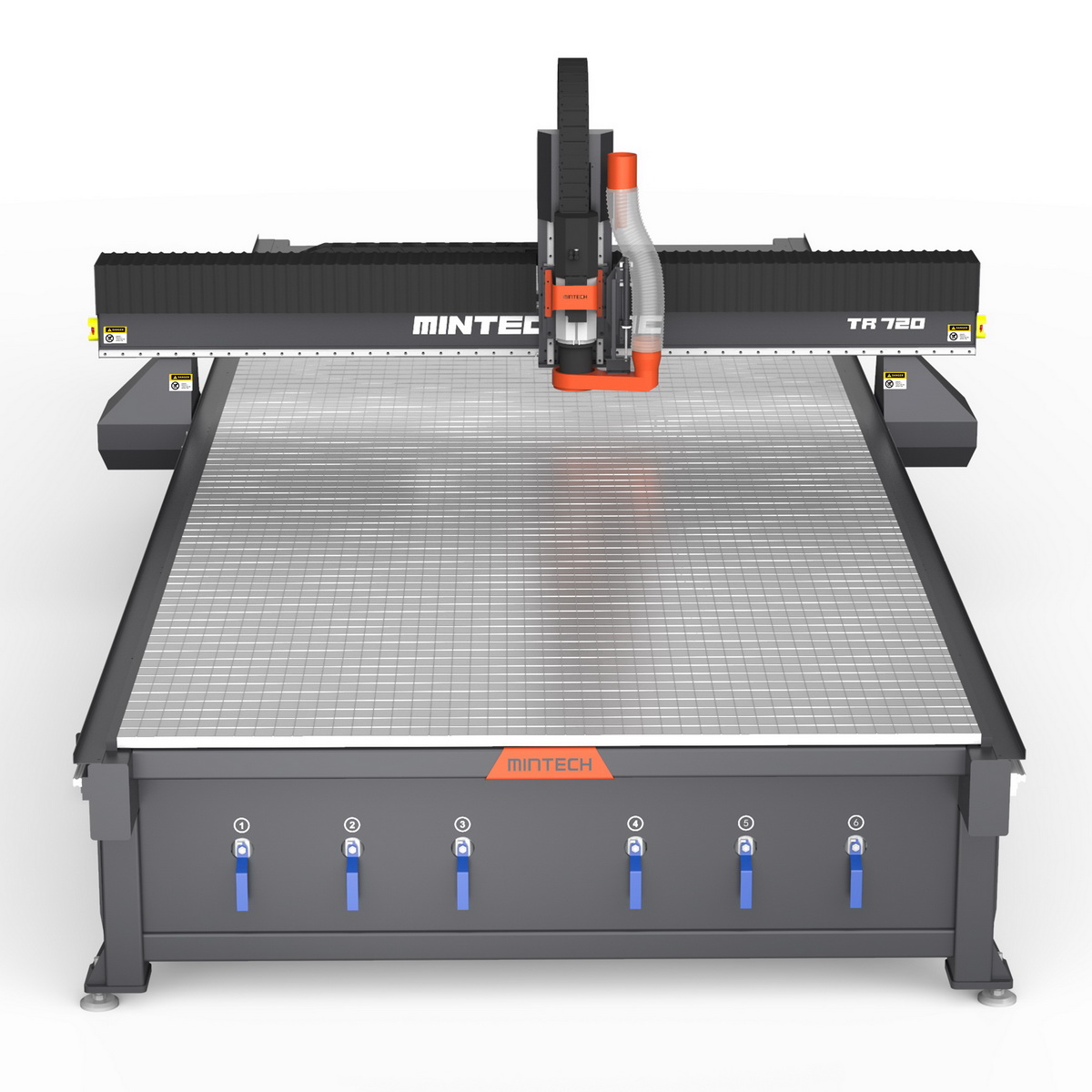

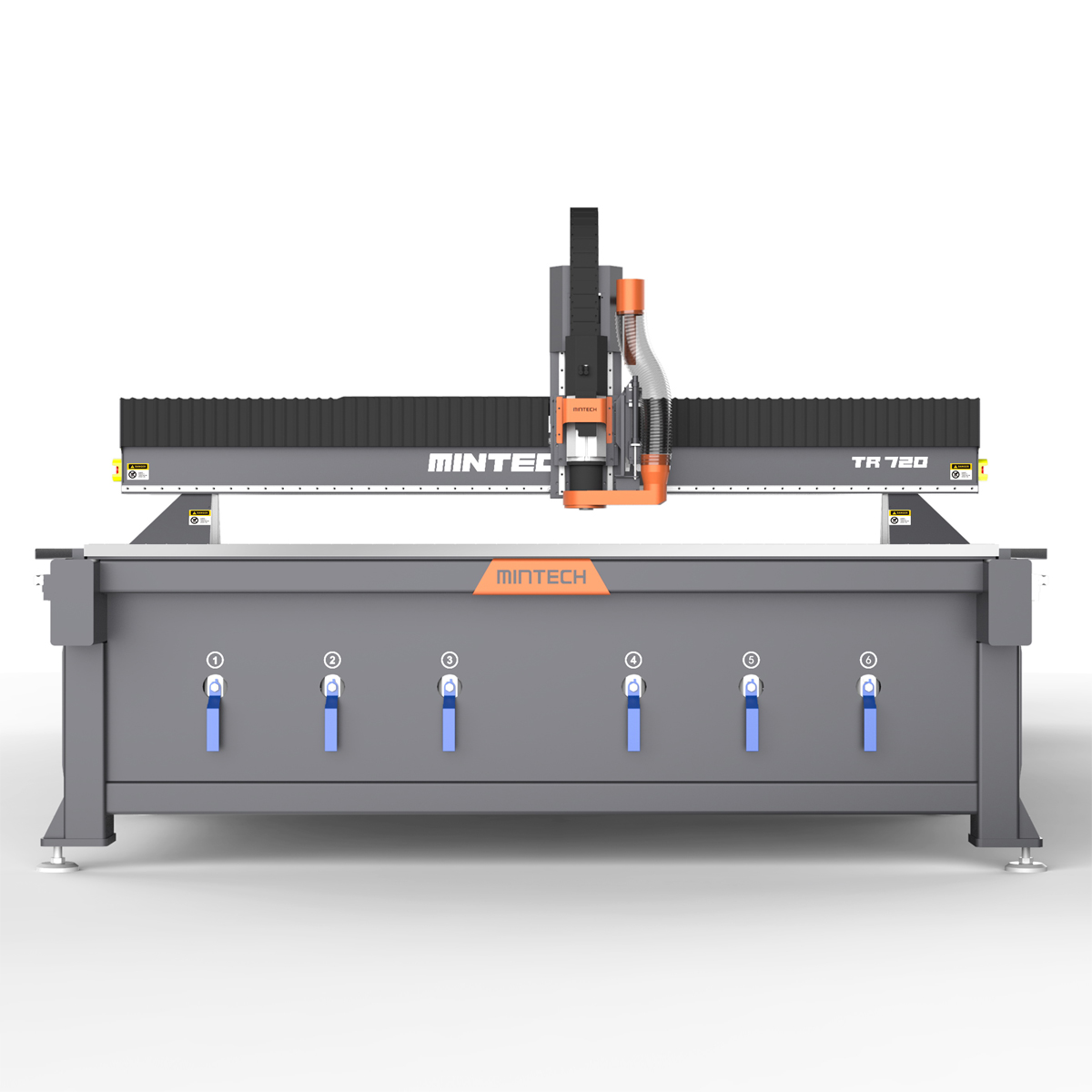

Model: TR720 Starting at $73000.00

In stock

In stock

* Free shipping within the continental U.S. on all online orders

Technical Specifications

| Model | TR48 | TR510 | TR720 |

|---|---|---|---|

| Working area | 4' × 8' ( 1250 × 2500 mm ) | 5' × 10' ( 1530 × 3060 mm ) | 7' × 20' ( 2000 × 6000 mm ) |

| Dimensions | 133" × 87" × 83" ( 3370 × 2200 × 2100 mm ) View image | 154" × 97" × 83" ( 3900 × 2450 × 2100 mm ) View image | 272" × 114" × 83" ( 6900 × 2900 × 2100 mm ) View image |

| Weight | 3400 lbs | 4500 lbs | 8900 lbs |

| Work Area and Capacity |

|

||

| Control System |

|

||

| CAM Software Compatibility | Compatible with industry-standard software like VCarve, Aspire, Alphacam, Engview, MasterCAM, Enroute, Type 3 and others | ||

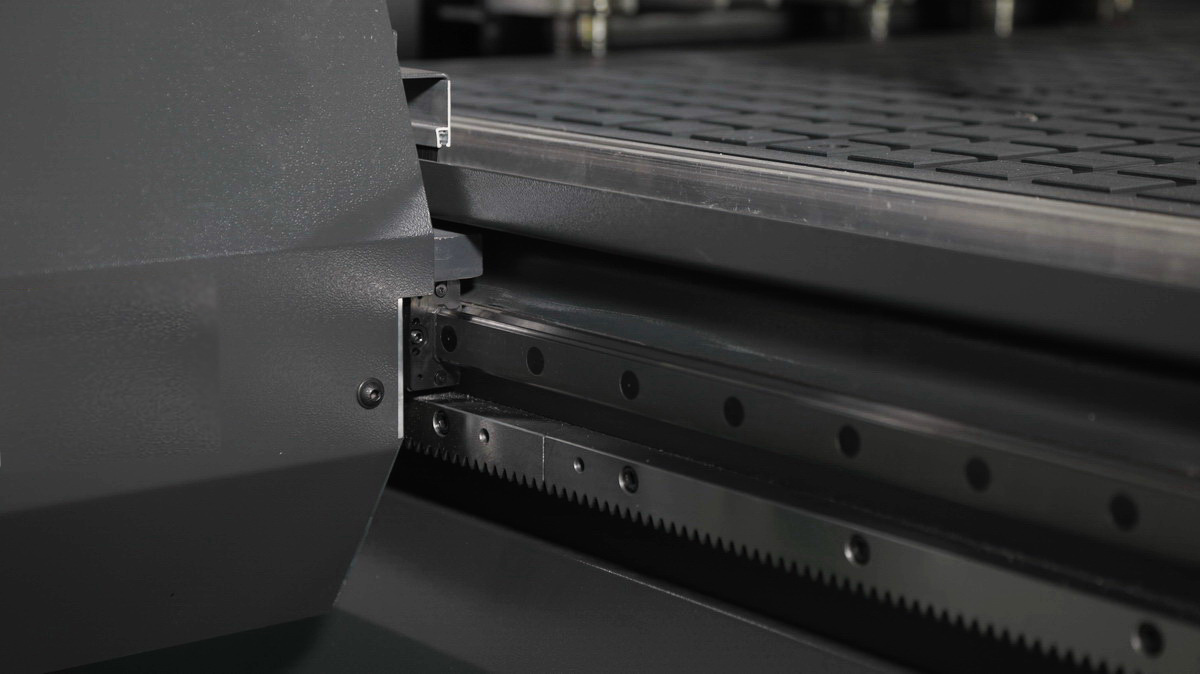

| Motion and Drive |

|

||

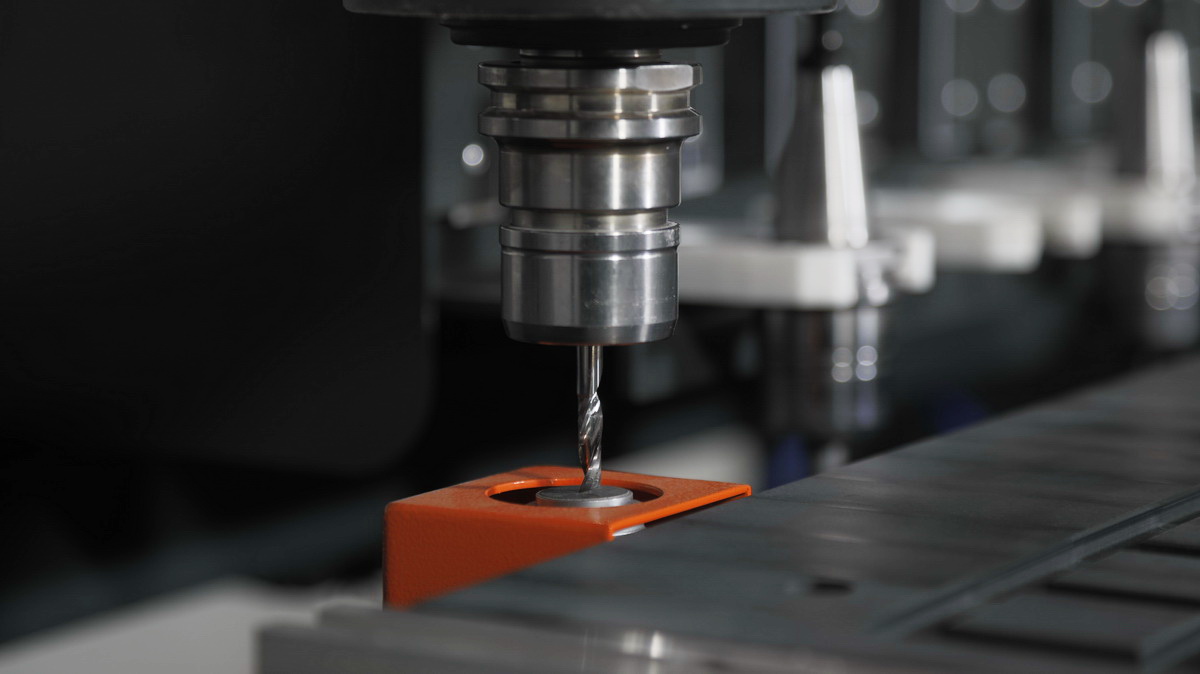

| Spindle |

|

||

| Power and Utility Requirements |

|

||

| Misting / Lubricating System | Includes flexible loc-line nozzles for adjustable coolant or mist delivery to the cutting area, ensuring efficient lubrication and extended tool life. | ||

| Environmental Requirements |

|

||

| Optional Upgrades |

|

||

| Advantages |

|

||

| Note: Specifications are subject to change without prior notice. | |||

TR48 - Industrial CNC router

TR510 - High precision affordable CNC router

TR720 - Oversized custom CNC router

Need Technical Support?

Our engineering team can help with product selection and configuration.

+1 (909) 755-1011

admin@mintechusa.com

Contact Engineering