CNC Routers

* Free shipping within the continental U.S. on all online orders

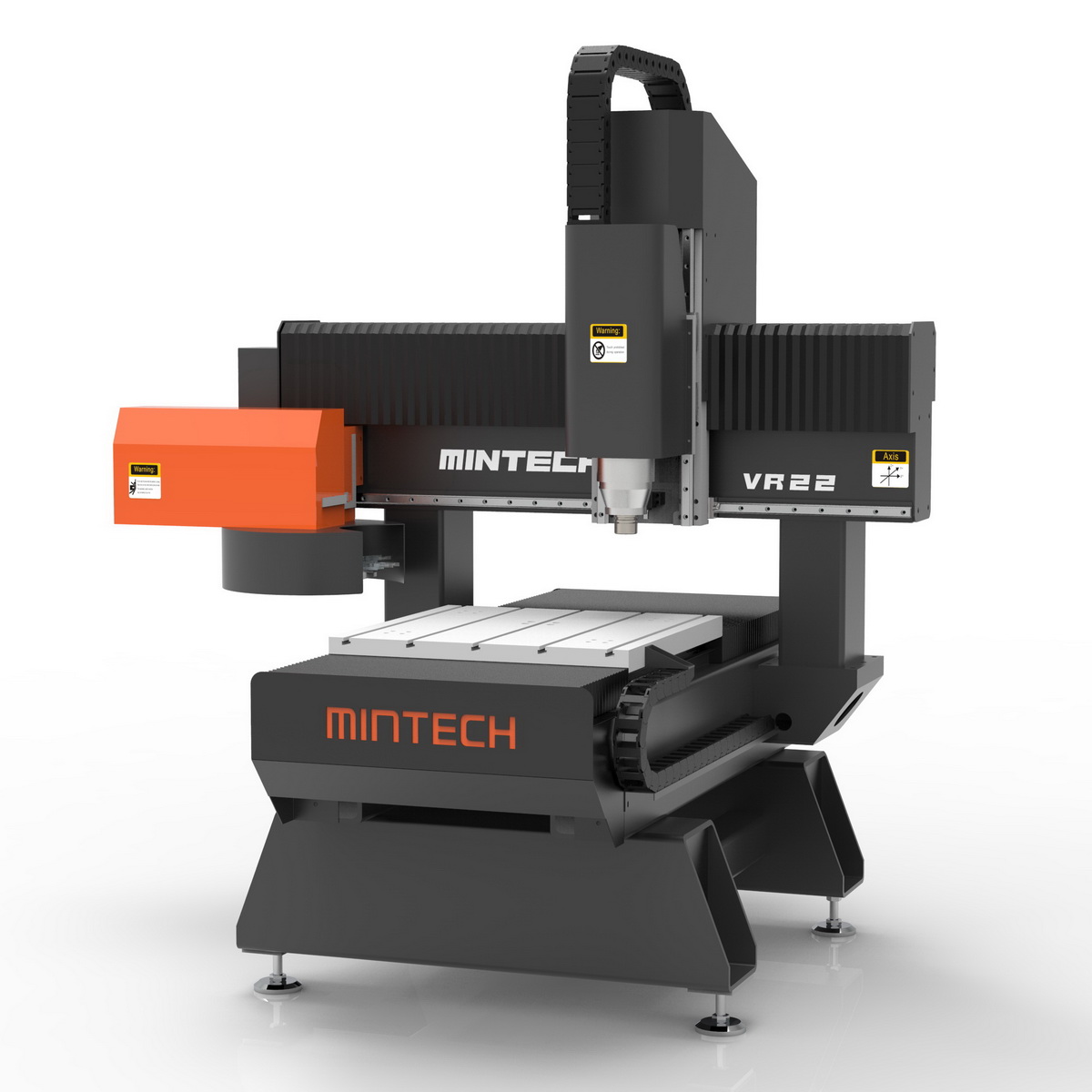

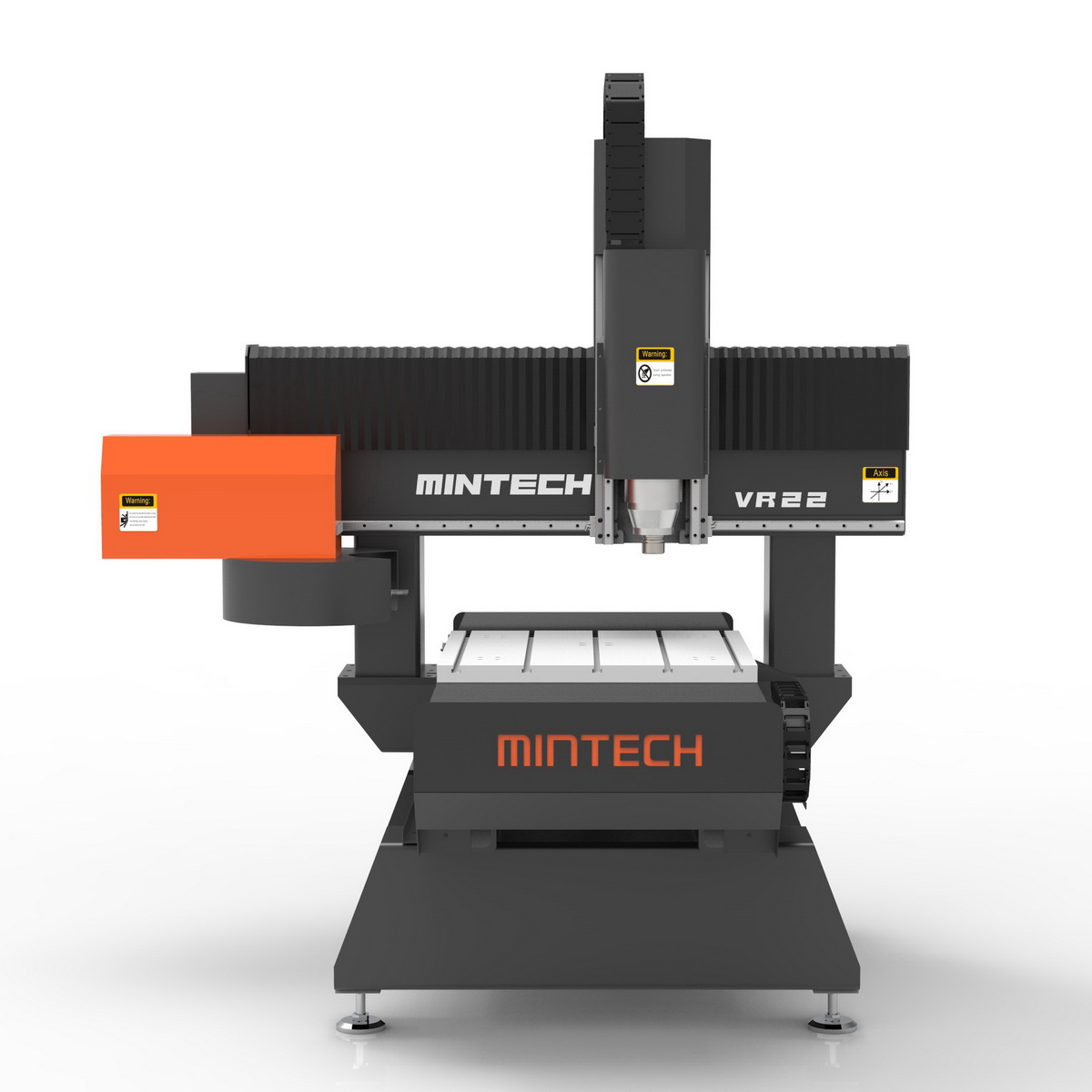

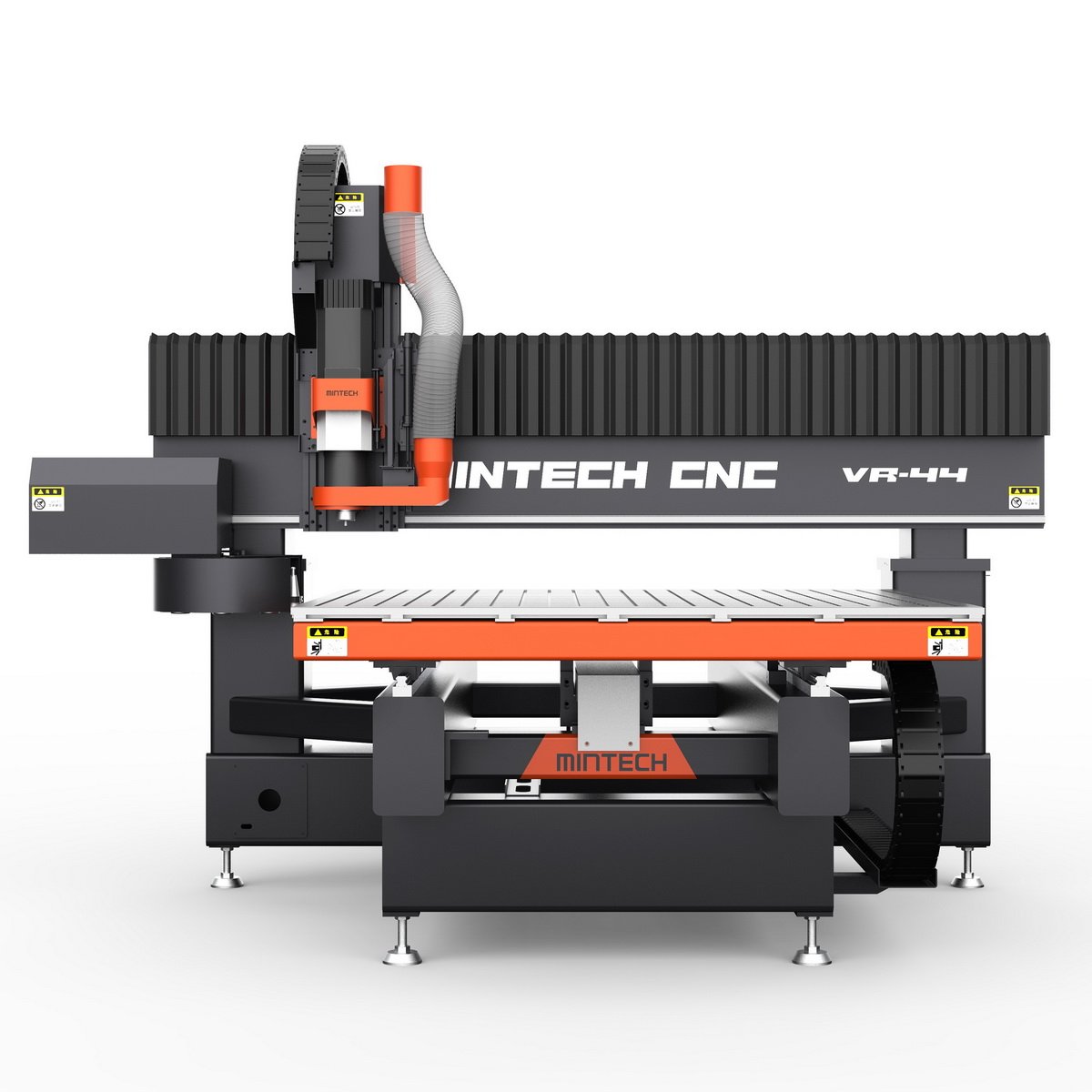

VR Series

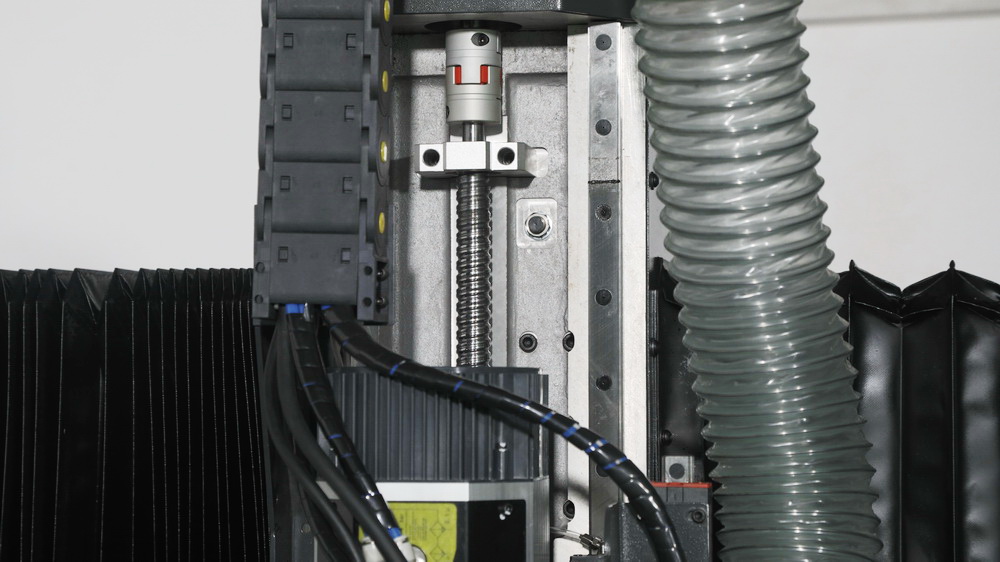

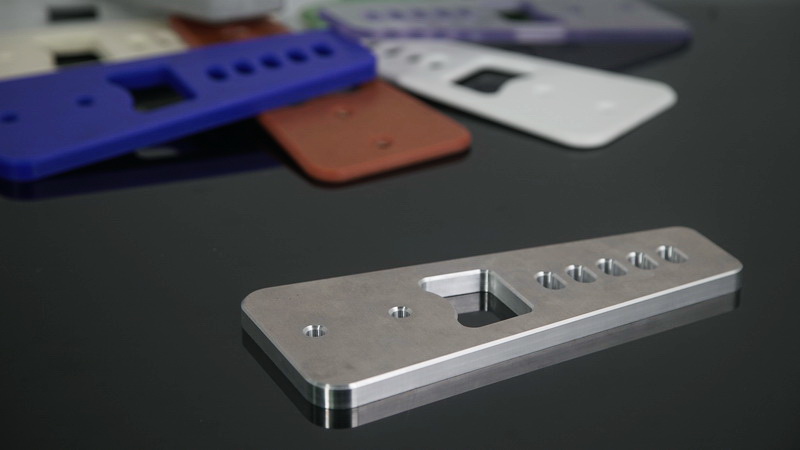

High-precision CNC router with ball screw transmission and moving table design. The VR Series CNC Router is a high-performance machine specifically designed for precision machining.

POWER SUPPLY

220V Three Phase

220V Three Phase

CONTROL SYSTEM

Weihong / Syntec / Siemens

Weihong / Syntec / Siemens

MOTOR TYPE

Servo Motor

Servo Motor

COOLING SYSTEM

Water Cooling / Air Cooling

Water Cooling / Air Cooling

SPINDLE POWER

4kW / 9kW

4kW / 9kW

SPINDLE RPM

40000 RPM / 24000 RPM

40000 RPM / 24000 RPM

Model: VR22 Starting at $33000.00

In stock

In stock

Model: VR44 Starting at $46000.00

In stock

In stock

Model: VR48 Starting at $51000.00

In stock

In stock

* Free shipping within the continental U.S. on all online orders

Technical Specifications

| Model | VR22 | VR44 | VR48 |

|---|---|---|---|

| Working area | 2'× 2' ( 610 × 610 mm ) | 4' × 4' ( 1250 × 1250 mm ) | 4' × 8' ( 1250 × 2500 mm ) |

| Worktable surface | T-slot aluminum table | Phenolic composite vacuum table with precision-milled grid and T-slot aluminum. | |

| Dimensions | 67" × 71" × 83" ( 1700 × 1800 × 2100 mm ) View image | 102" × 87" × 90" ( 2600 × 2200 × 2300 mm ) View image | 146" × 87" × 90" ( 3700 × 2200 × 2300 mm ) View image |

| Weight | 1800 lbs | To Be Determined | |

| Z-Axis Travel | 11 inches ( 280 mm ) | 13 inches ( 330 mm ) | |

| Material Thickness | Up to 5 inches ( 130 mm ) | Up to 7 inches ( 180 mm ) | |

| Cutting Thickness | Up to 4 inches ( 100 mm ) with appropriate tooling. | ||

| Spindle Power | 5.3 HP (4 kW), 4,0000 RPM | 12 HP (9 kW), 24,000 RPM | |

| Cooling method | Water Cooling | Air Cooling | |

| Spindle Options | Hiteco or HSD spindles. | ||

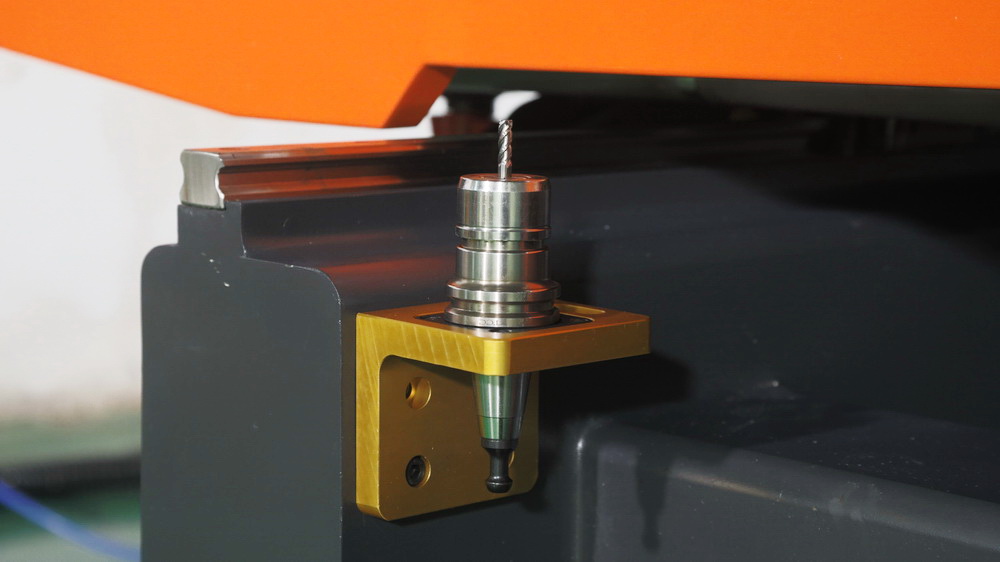

| Tool Holder | ISO 20 | ISO 30 | |

| Tool Clamping | ER 20 | ER32 | |

| Tool Changing System | 6-position rotary tool changer | 8-position rotary tool changer | |

| Control System |

|

||

| CAM Software Compatibility | Compatible with industry-standard software like VCarve, Aspire, Alphacam, Engview, MasterCAM, Enroute, Type 3 and others | ||

| Drive System |

|

||

| Spindle |

|

||

| Power Requirements |

|

||

| Misting / Lubricating System | Includes flexible loc-line nozzles for adjustable coolant or mist delivery to the cutting area, ensuring efficient lubrication and extended tool life. | ||

| Environmental Requirements |

|

||

| Available Configurations |

|

||

| Advantages |

|

||

| Note: Specifications are subject to change without prior notice. | |||

VR22 Precision CNC Router

VR44 Ultra-precision CNC Router

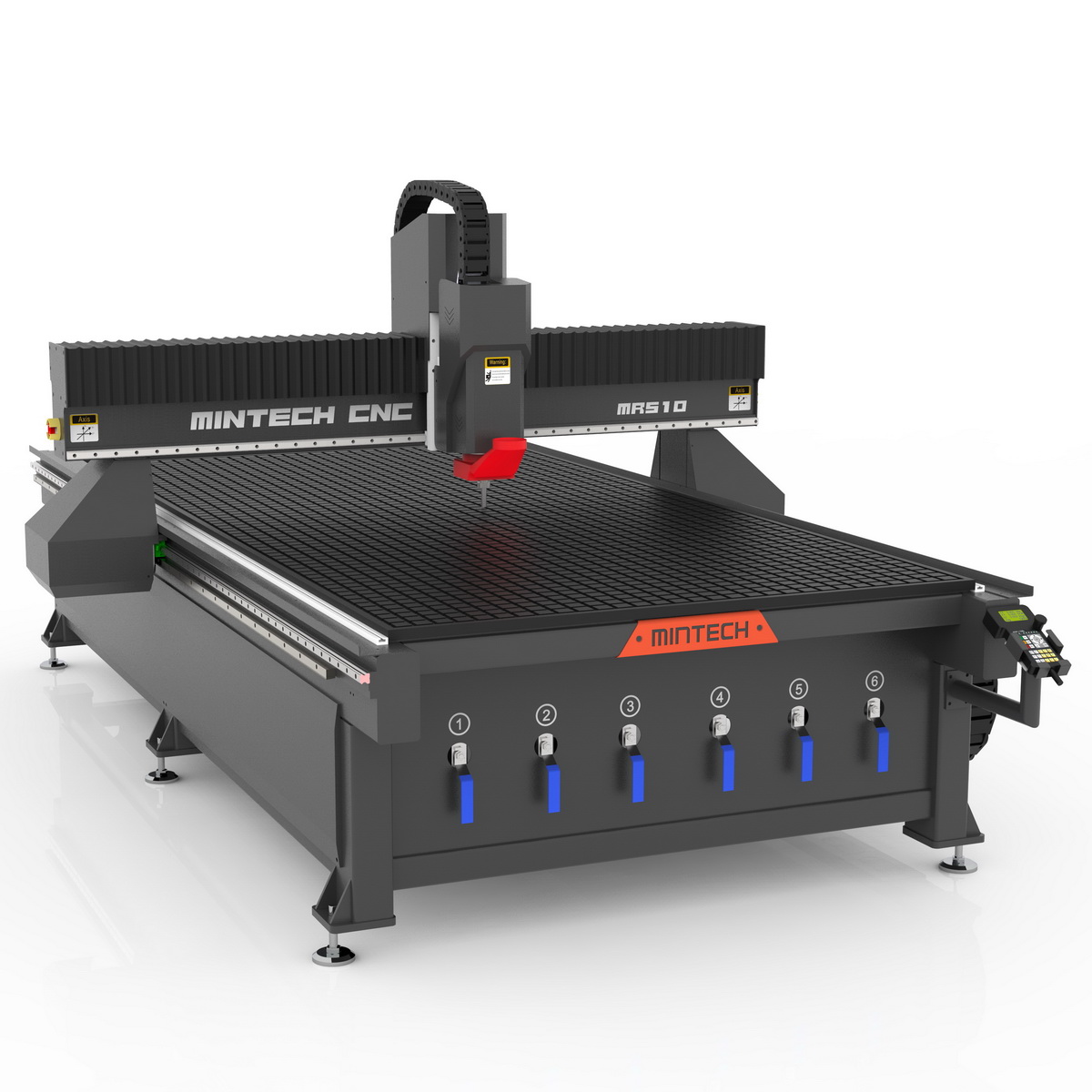

VR48 Plastic/Aluminum Cutting Machine

Need Technical Support?

Our engineering team can help with product selection and configuration.

+1 (909) 755-1011

admin@mintechusa.com

Contact Engineering